-

Why does the addition-type liquid silicone not cure? How to solve it?...

Because the addition-type silicone is formed by adding platinum catalyst. Once the platinum catalyst comes into contact with elements containing nitrogen, sulfur and phosphorus or heavy metal compounds (lead, etc.), or smokes in the operating space, it will react with nitrogen, sulfur and phosphor...

See More

-

What is the effect of temperature on the curing time of mold silicone?...

Mold silicone is divided into condensation mold silicone and addition mold silicone, both of which can be used to make molds. To know the effect of temperature on the curing time of mold silicone, you might as well start from the physical properties between them. Condensation mold silicone is co...

See More

-

How to deal with the air bubbles in the mold making process?

There are three solutions for the air bubbles in the mold making process: 1. Degassing the mixture in vacuum machine. Put the mixture into the vacuum machine after you mix the silicone base and catalyst thoroughly. This degassing process will take 3-5 minutes. 2. If there is no vacuum machine...

See More

-

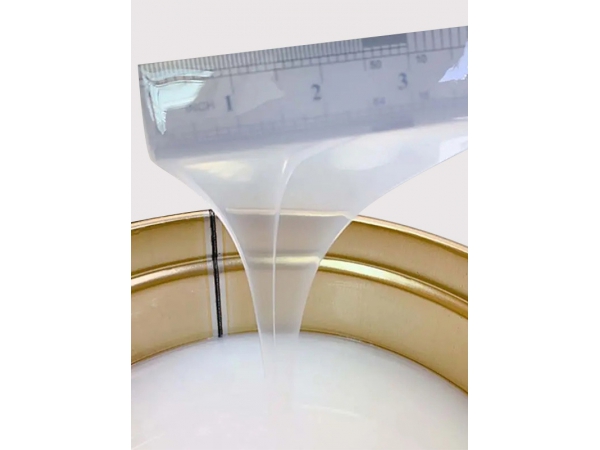

How to use the tin cure silicone for mold making?

1. Mixing of the two components To 100 parts of silicone base add 2~3 parts of the selected catalyst. The two components are thoroughly mixed either using an electrical or pneumatic mixer on a low speed setting so as to limit the inclusion of air in the mixture as well as temperature rise. 2. ...

See More

-

What are the major differences between tin-cure and platinum-cure silicone mold making rubbers?...

Here at DUOMI SILICONE we sell 2 types of silicone, condensation cure and addition cure. These are the two main types of RTV silicones used for mould making and casting. Tin-cure(Condensation cure) uses a tin based catalyst, Platinum-cure(addition cure) uses a platinum based ca...

See More

-

Why is liquid silicone rubber becoming more and more popular?...

1. Excellent physical and chemical properties: Liquid mold silicone has excellent fluidity, good operability, no deformation, high temperature resistance, acid and alkali resistance, no expansion, good tensile strength, and good tear strength. These characteristics make liquid mold silicone exc...

See More